Building Moatshark

Moatshark (and moat) build guide

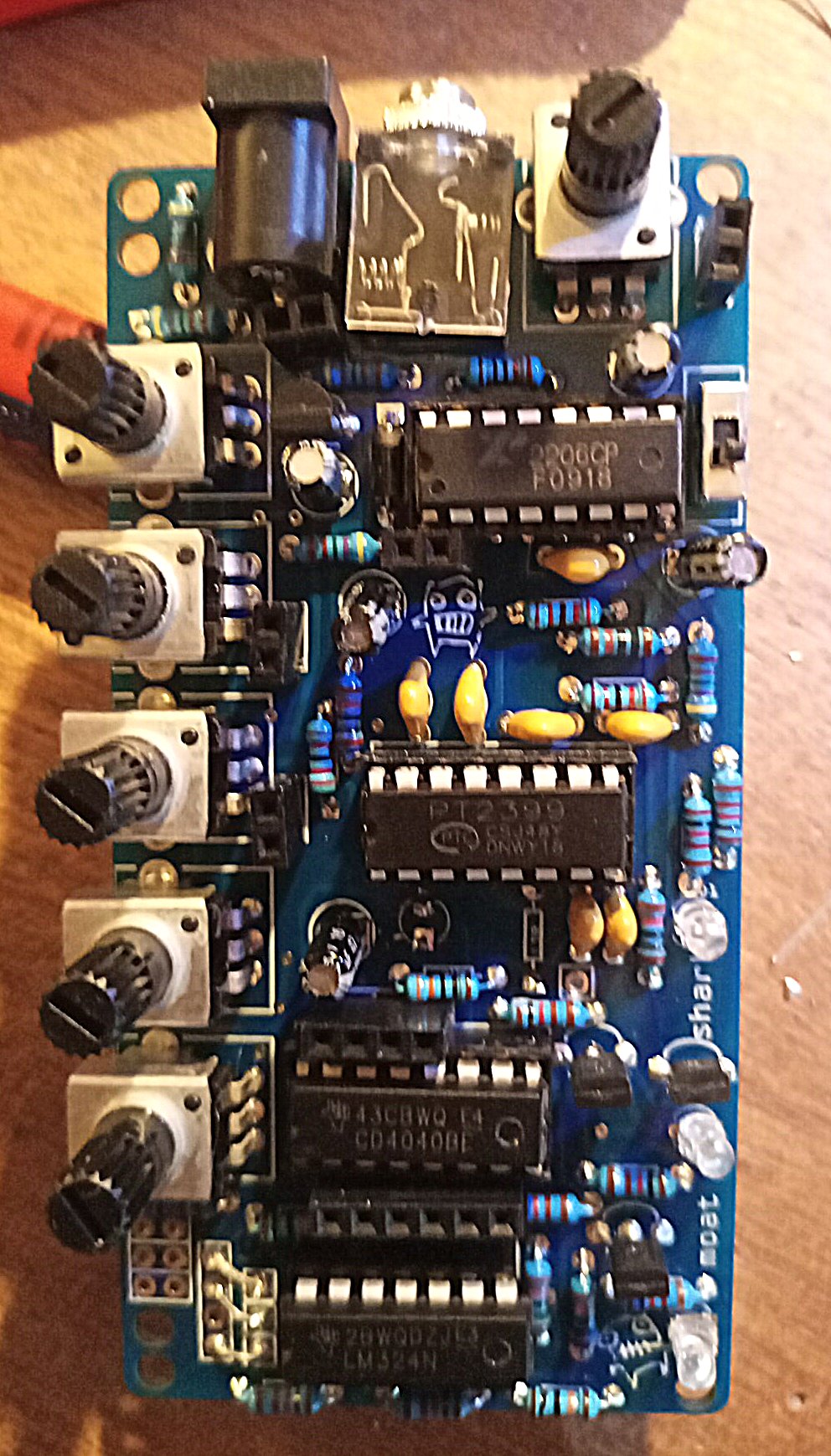

Although this guide is explicitly for the moatshark, it’s mostly identical with that of moat. Moat has one more 4040 and no vactrols, but the rest is very close to the same. and the steps and order in any case.

Assemble (yourself)

- Get coffee

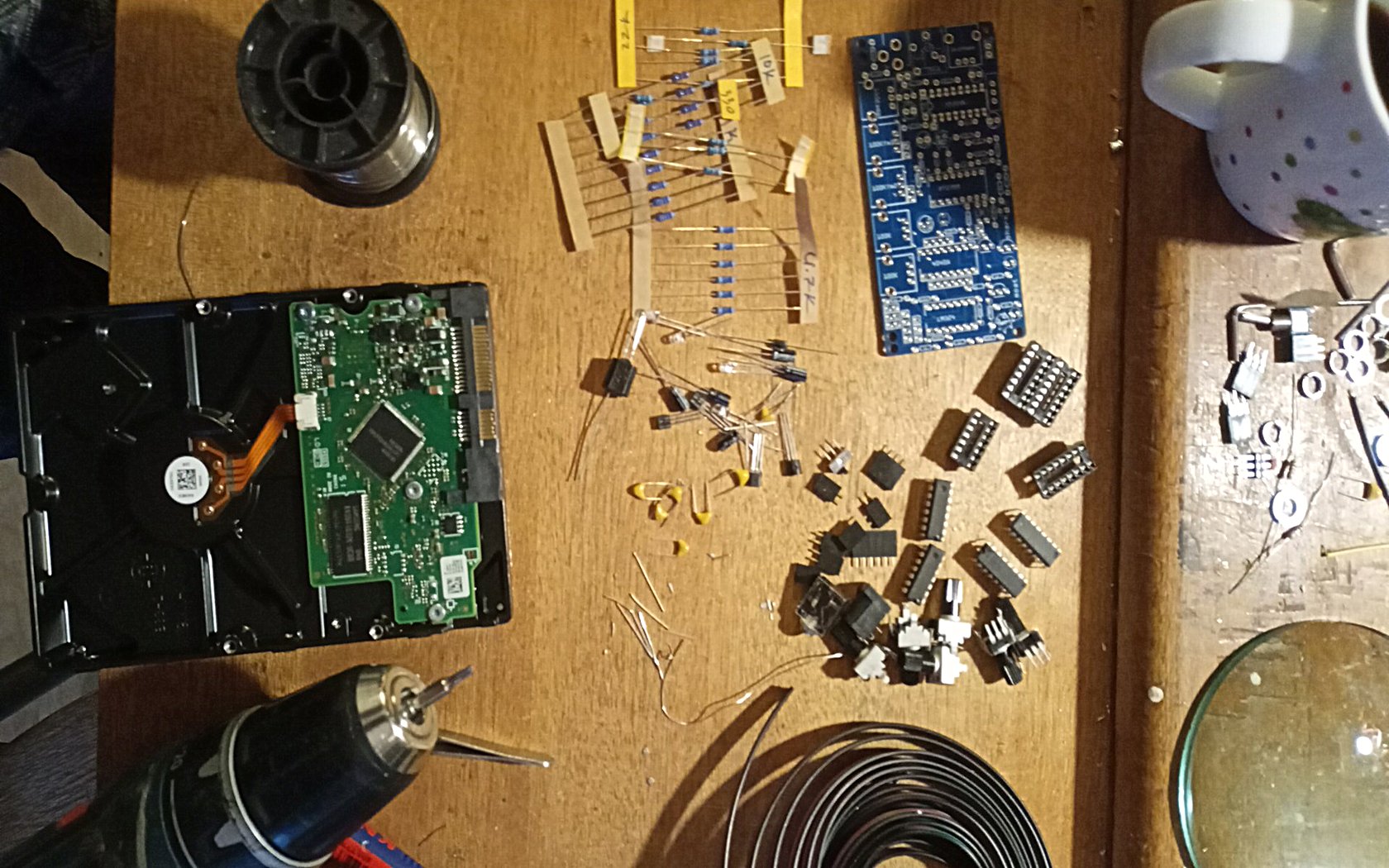

- gather tools (hacksaw, hammer, hammer kidding).

- Soldering iron, solder (I use .5mm solder)

- clippers

- kneedle nose pliers (or similar)

- tweezers?

- I need a magnifying glass

- small screw drivers

- small allen keys/hex wrench

- multimeter? I like em.

- just some ideas, it’s an art, damn it

- Sigh deeply.

prep tools

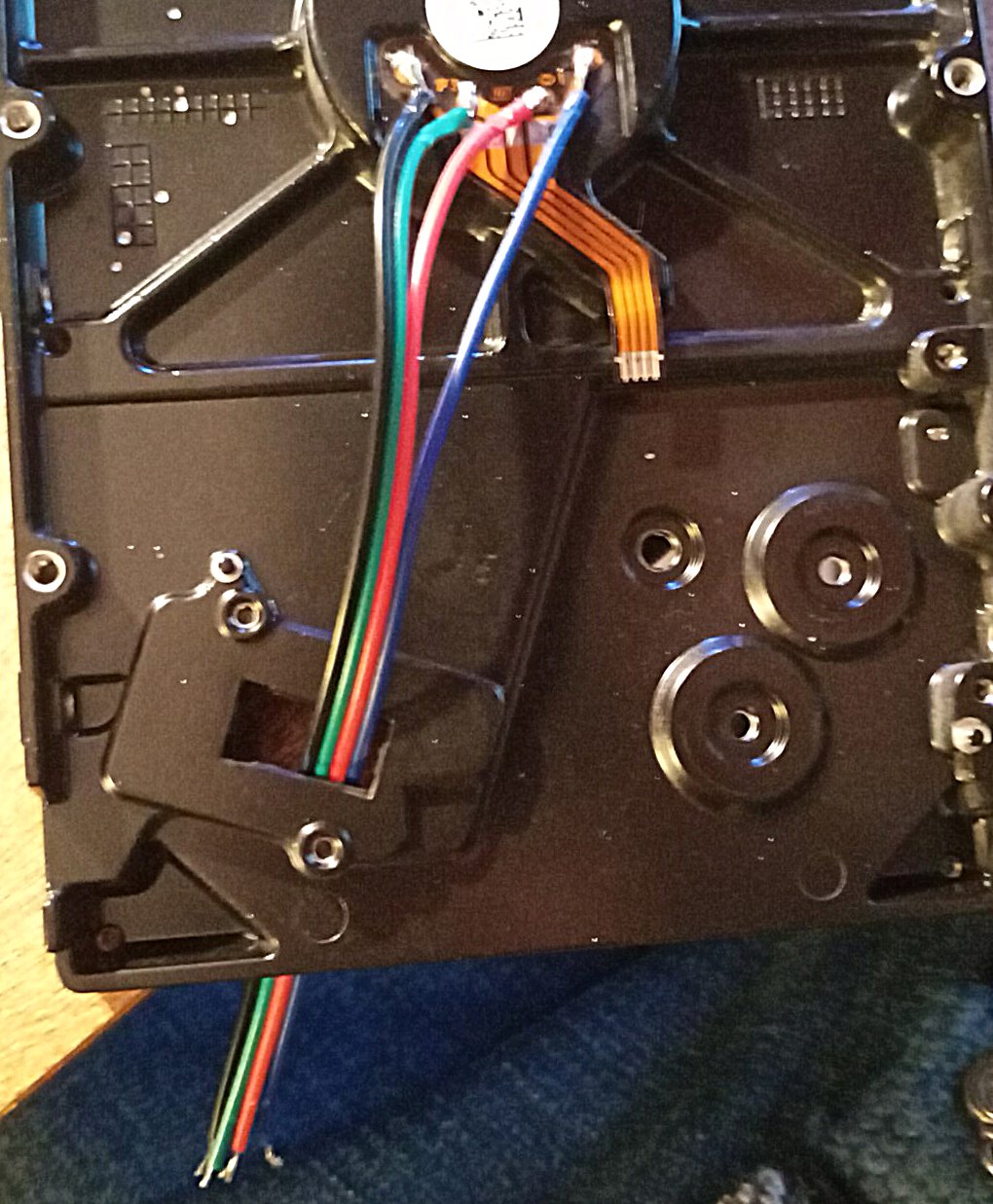

I begin buy preparing the drive, although it only comes into play at the end, I start here so it’s ready when I need it.

If it’s not already dissasembled (i ship with this done), take it apart :) You can choose to leave the read head in, but for this build I always remove it. In theory, one could feedback a signal to the read head to make it move. But I don’t consider this in this circuit.

prep disk

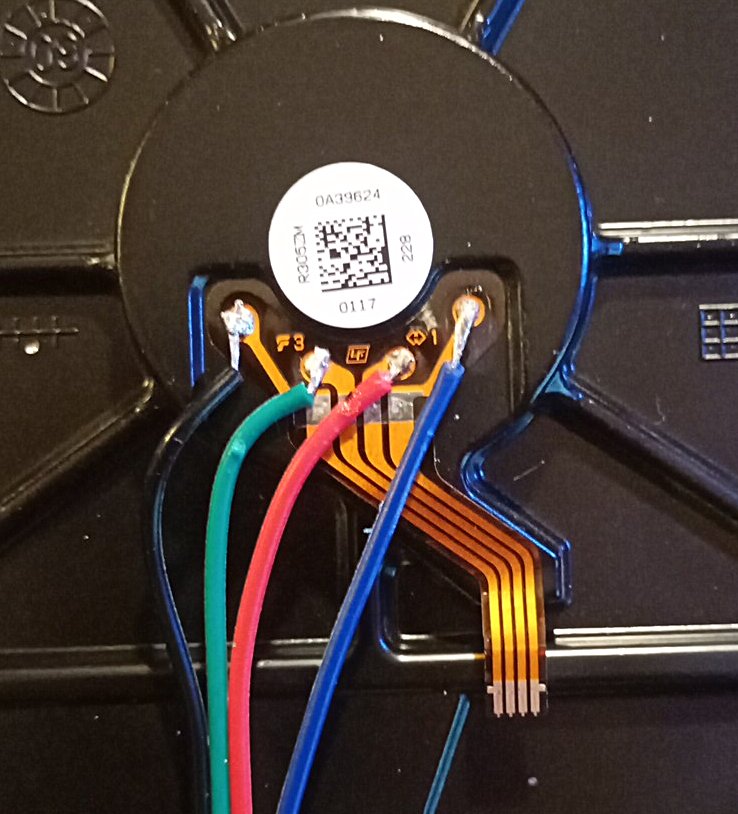

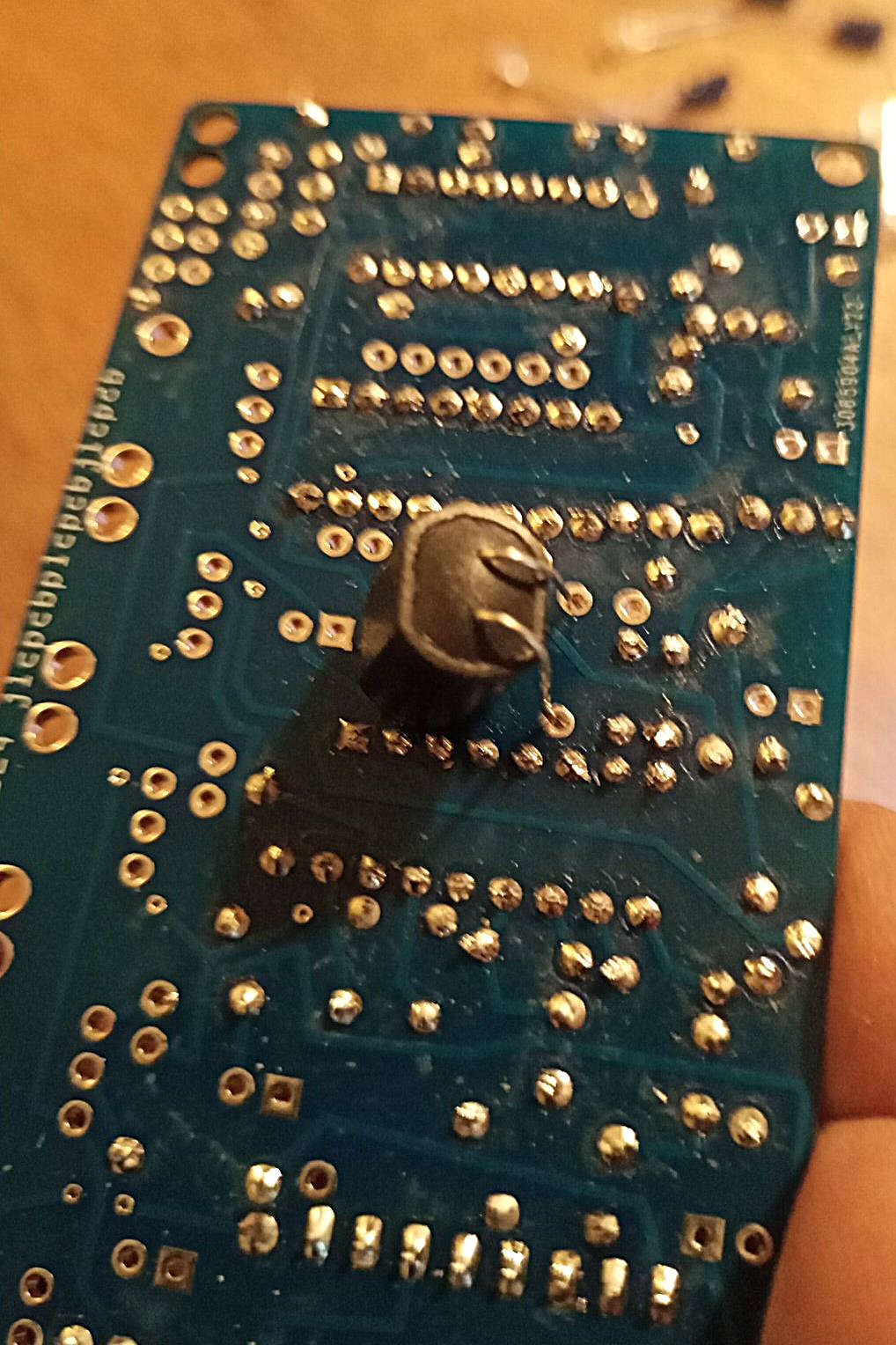

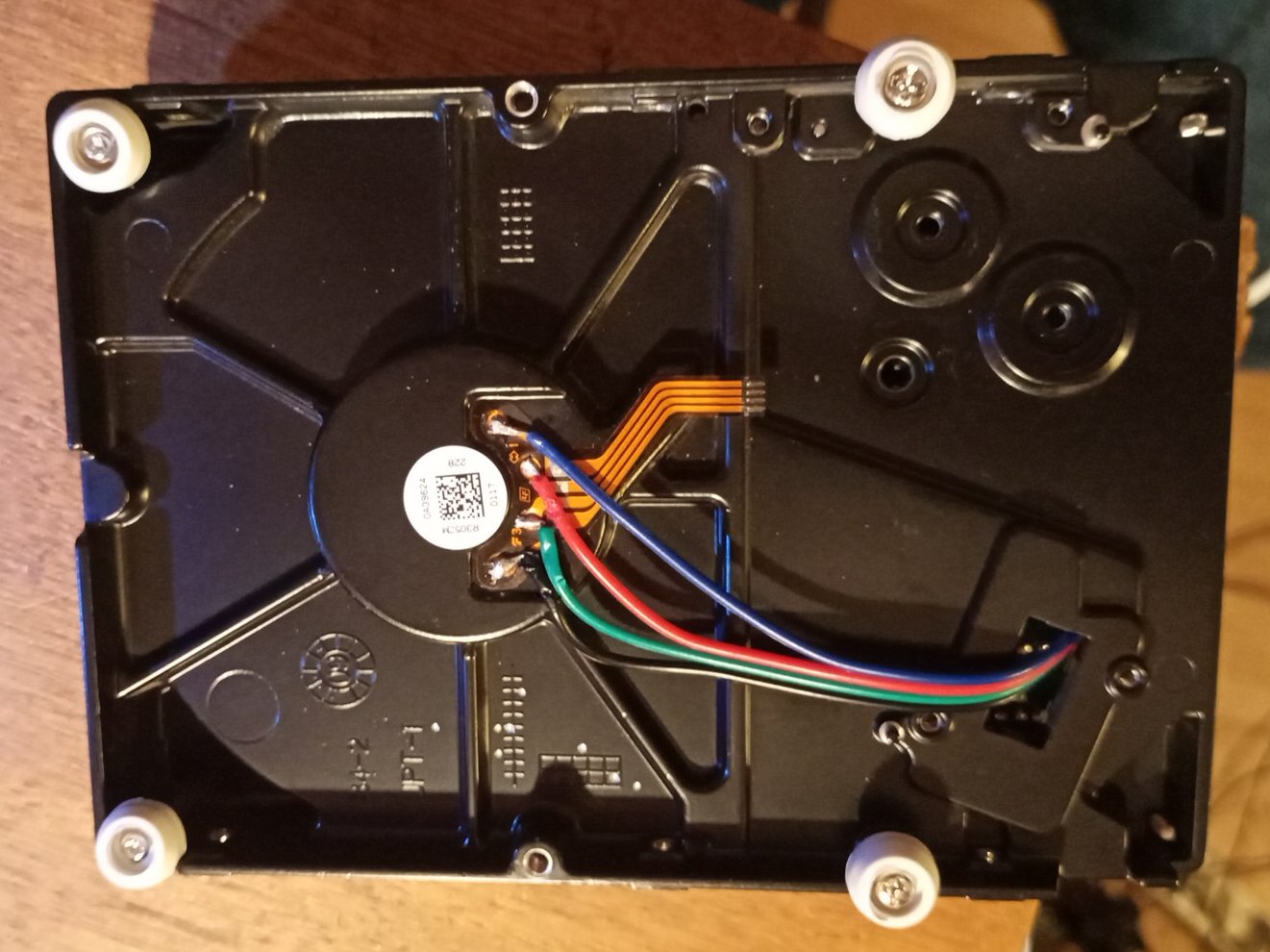

Strip the cable assembly 4 wires and solder to the 4 points on the bottom of the drive as shown here. By adjusting the lengths you cut, you can get more creative / better alignment than I have here. In this case, I’ve just bent the wires a bit.

I use black for the common wire (in the drives I supply, on the far left). The resistance between each of the other three will be higher than the resistance between the common one and the others. The three ‘motor’ wires will deliver the signals we use. The resistance between the motor terminals is equal, the common connector lower. With the drives I supply, you can just follow along.

prep disk

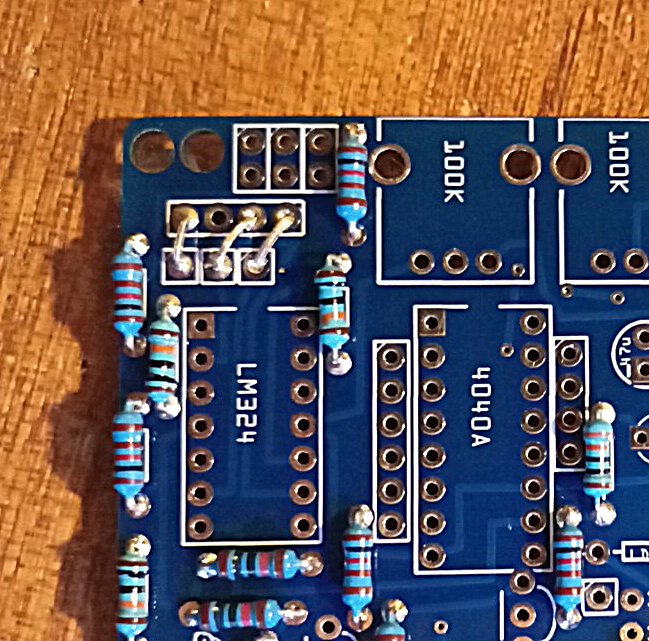

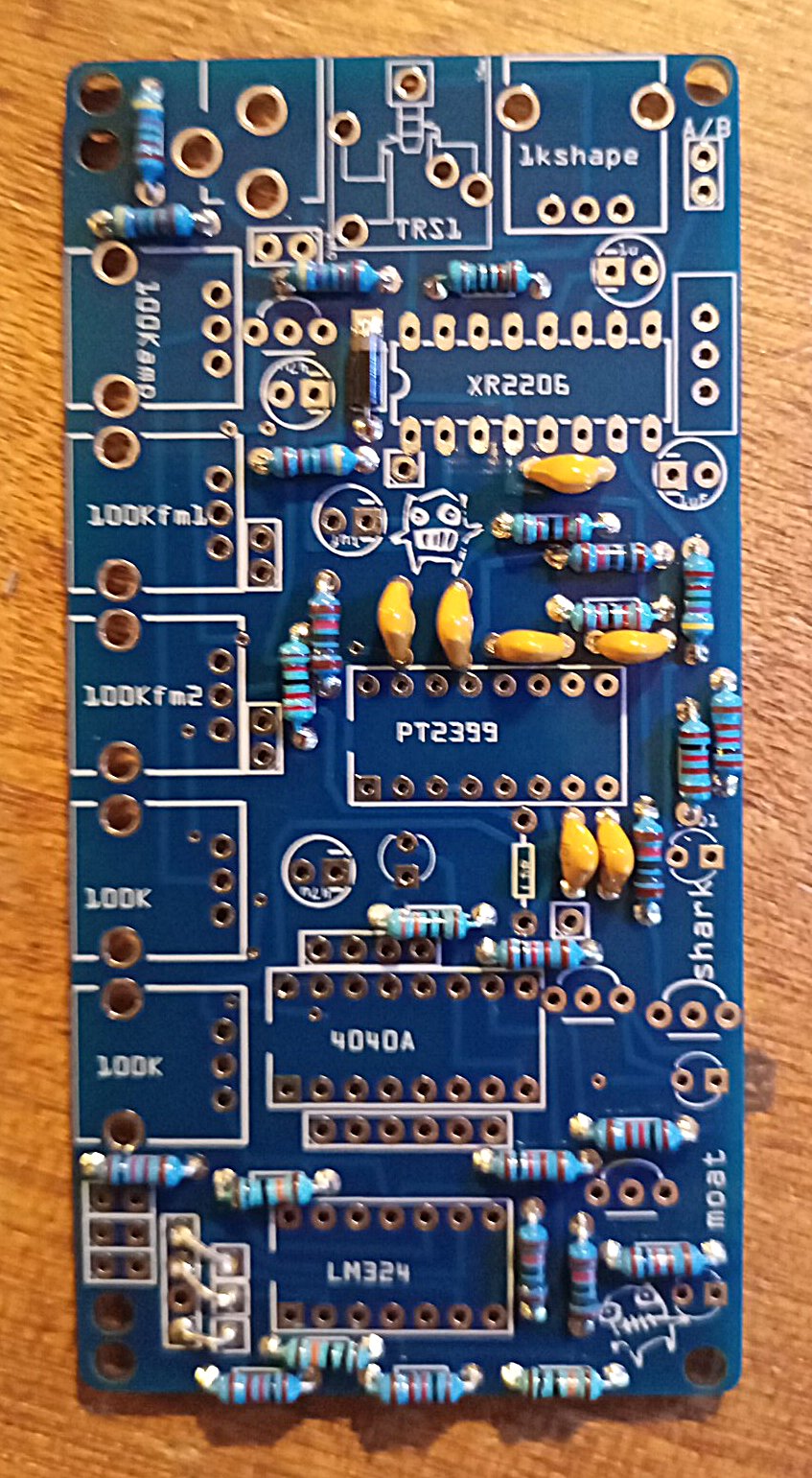

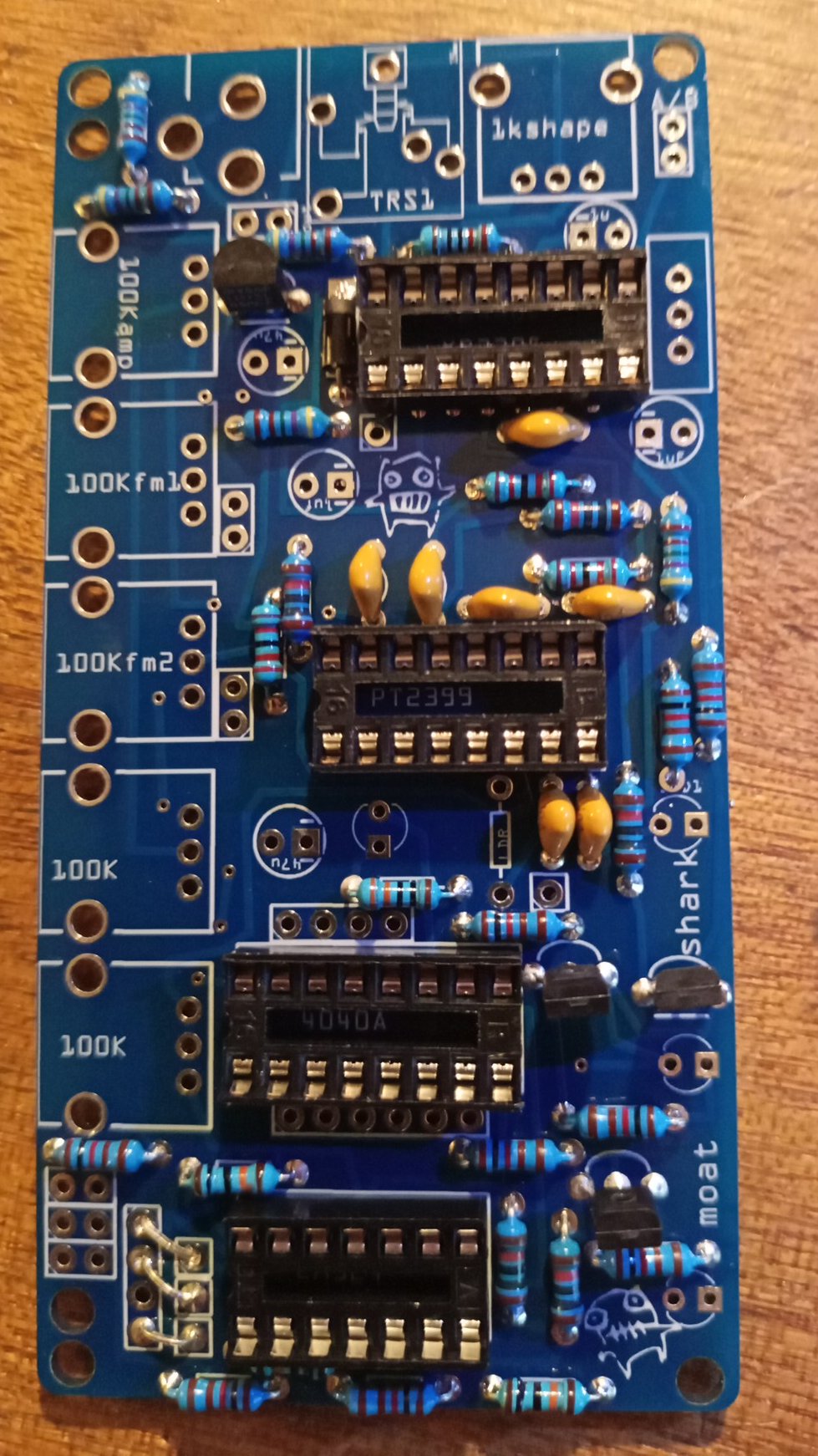

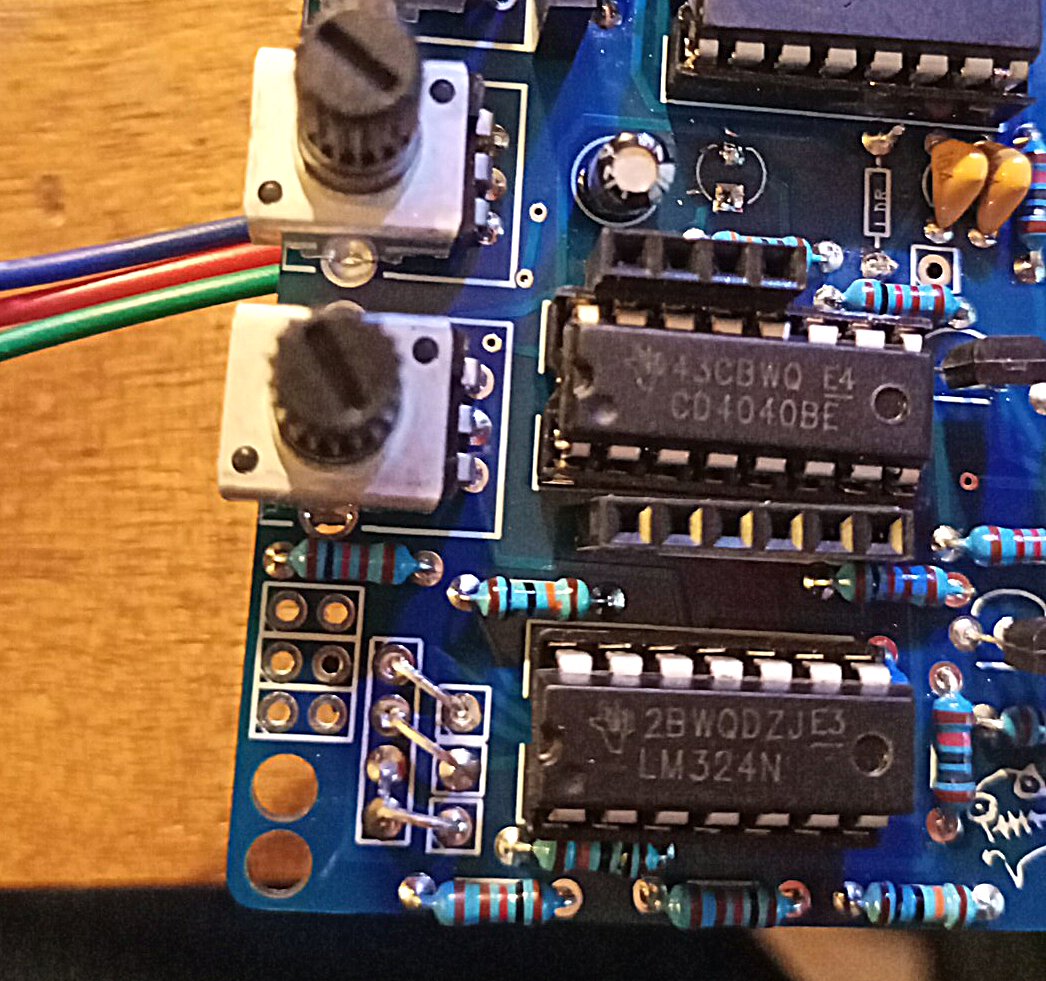

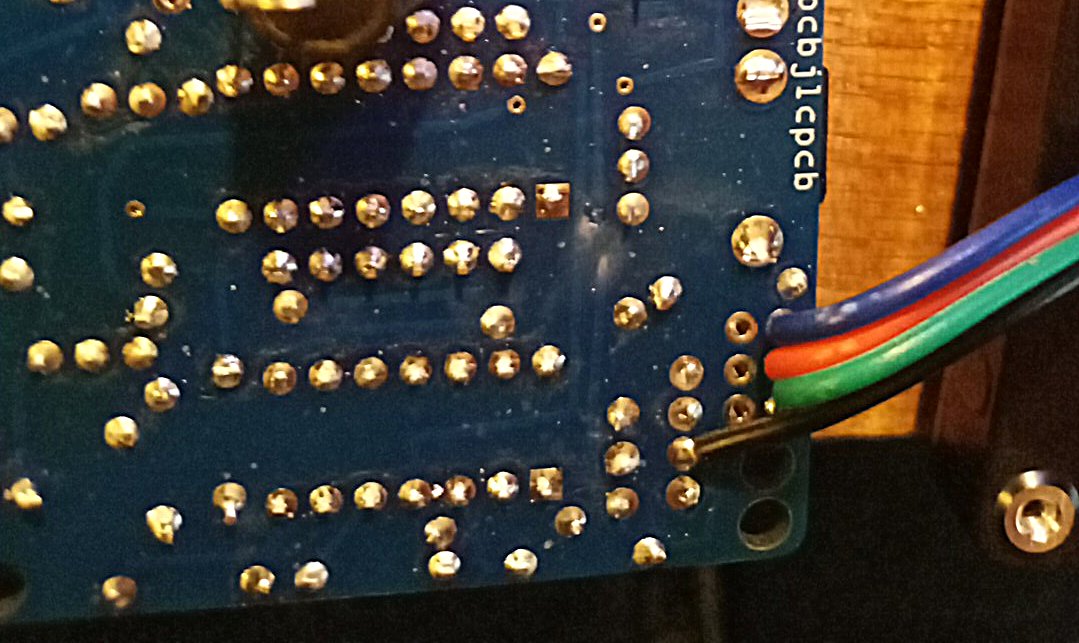

Onto the board! We start by placing all the low bits first. So, some jumper wires seen here in closeup and the resistors. The jumper wires are here since two disk layouts are supported by the board. But we’re using one with a common wire. The space between jumpers will have the black common wire solderd in at the end.

jumpers and resistors

Solder the diode and capacitors.

diode and caps

Now we add the vactrol, between the PT2399 and the 4040A. It goes on the bottom of the board! The LED side of the vactrol has a longer and a shorter wire. That longer wire goes in the square hole. The LDR side is simple.

VACTROL!

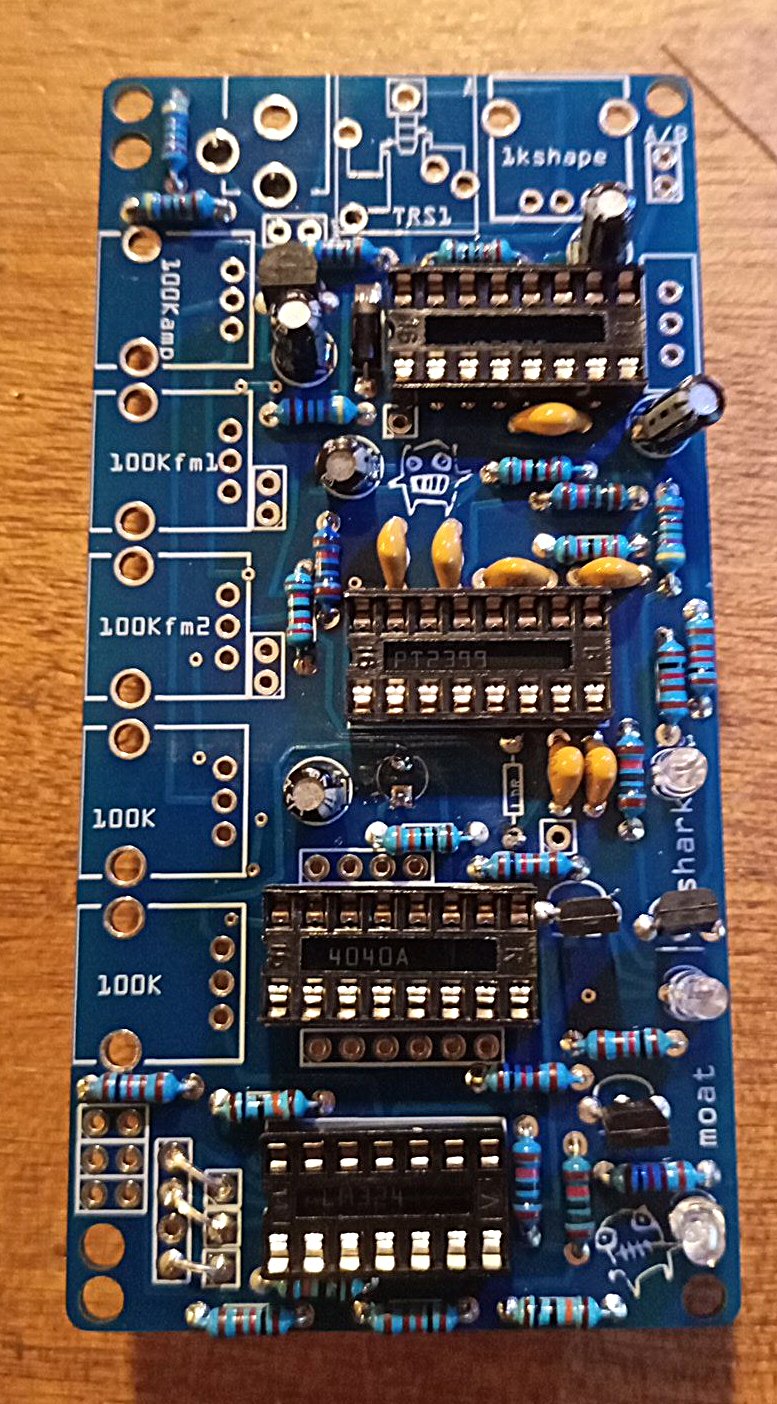

Now we add the IC sockets. In this build, I actually forgot to do the Vactrol first. It’s a pita. So vactrol first, then IC sockets. Since everything is still low, you should be able to rest the board on the sockets for soldering. I usually do two pins on diagonals holding the socket to the board first with each socket. Then I rest the board on the sockets and complete soldering. In the following pics I’ve already added the transistors, but that’s next step.

IC sockets

Then, as you can see above, I add the transistors and the 5 volt regulator. The rounded bits of the transistors / dc voltage regulator match the rounding on the pcb.

After the transistors I add the LEDs and then the electrolytic capacitors. For the elkos, then negative side (short wire) goes in the square holes. It’s the opposite with the leds. The long leg of the leds goes into the square holes. Don’t ask why.

transistors, LEDs and elkos

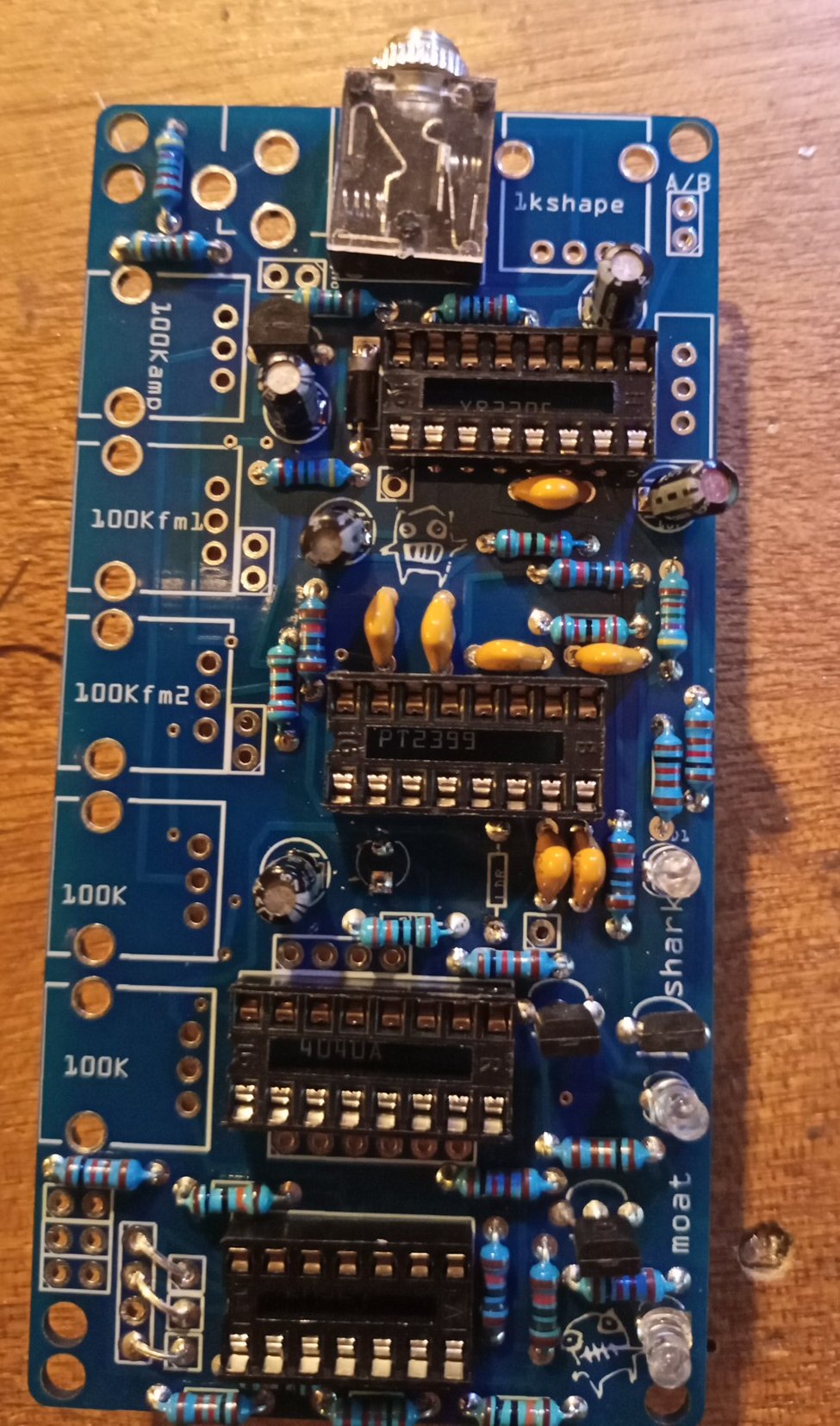

Now we add the audio jack

audio jack

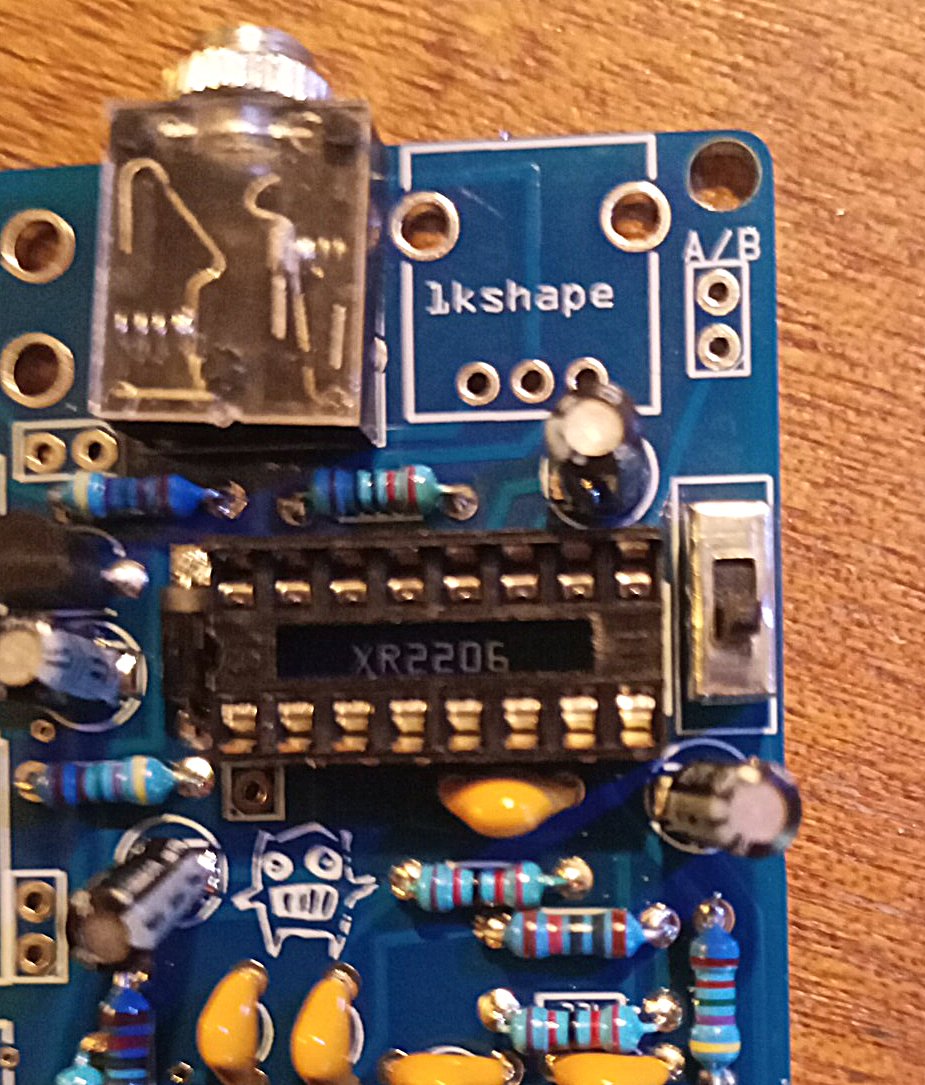

And the small switch next to the XR2206

small switch

Begin soldering the input sockets as seen here. Start with these three…

sockets

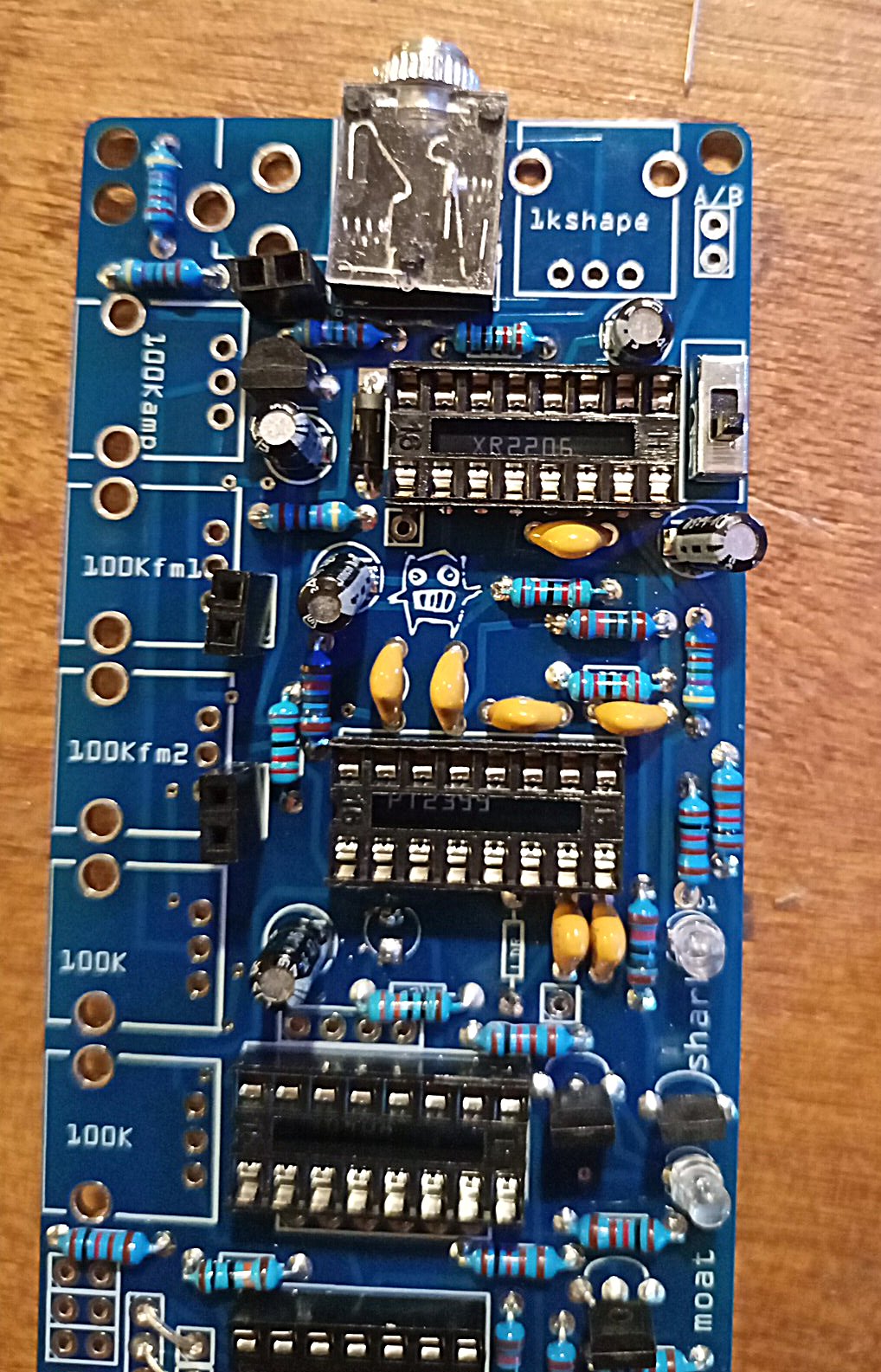

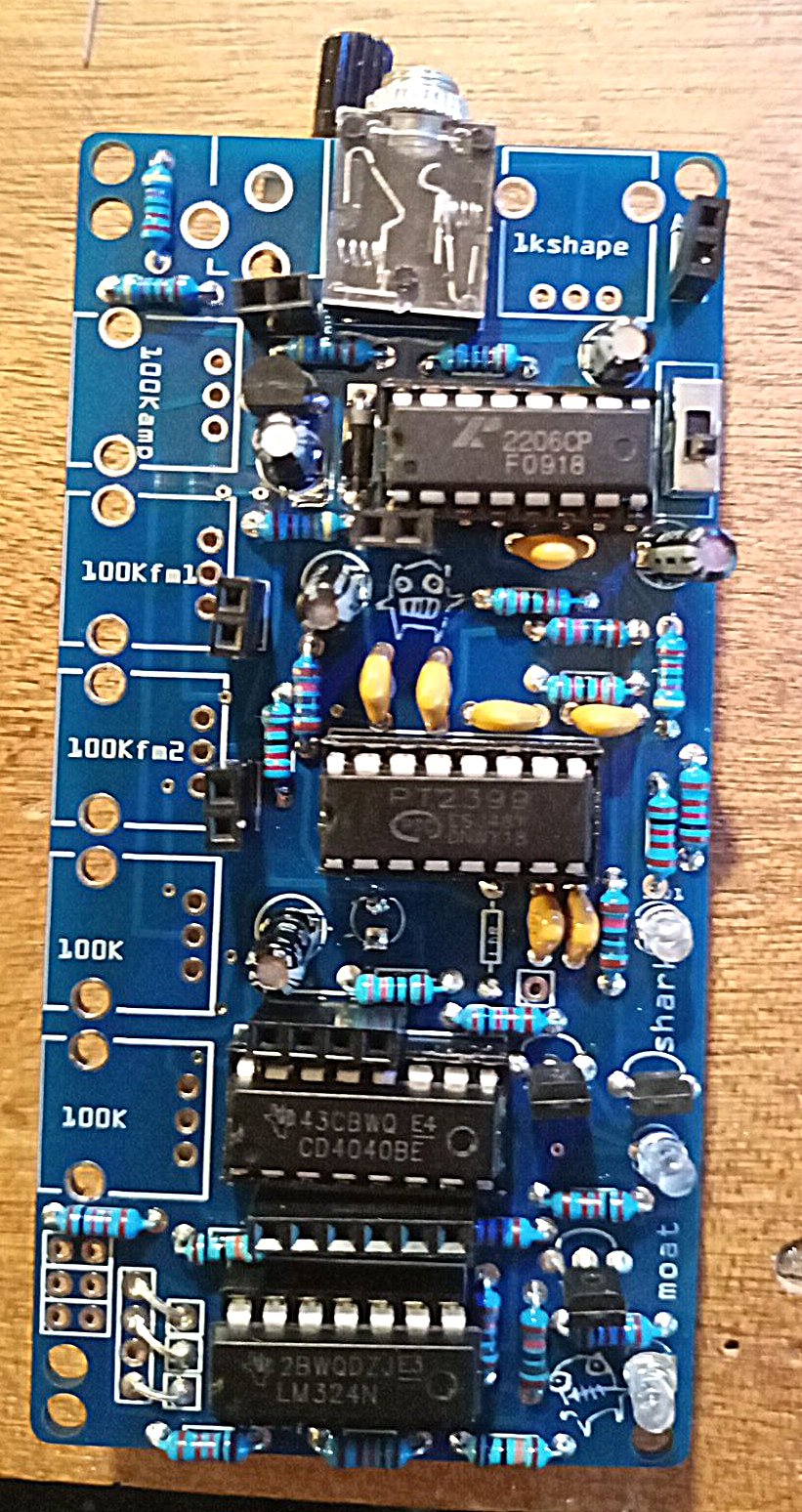

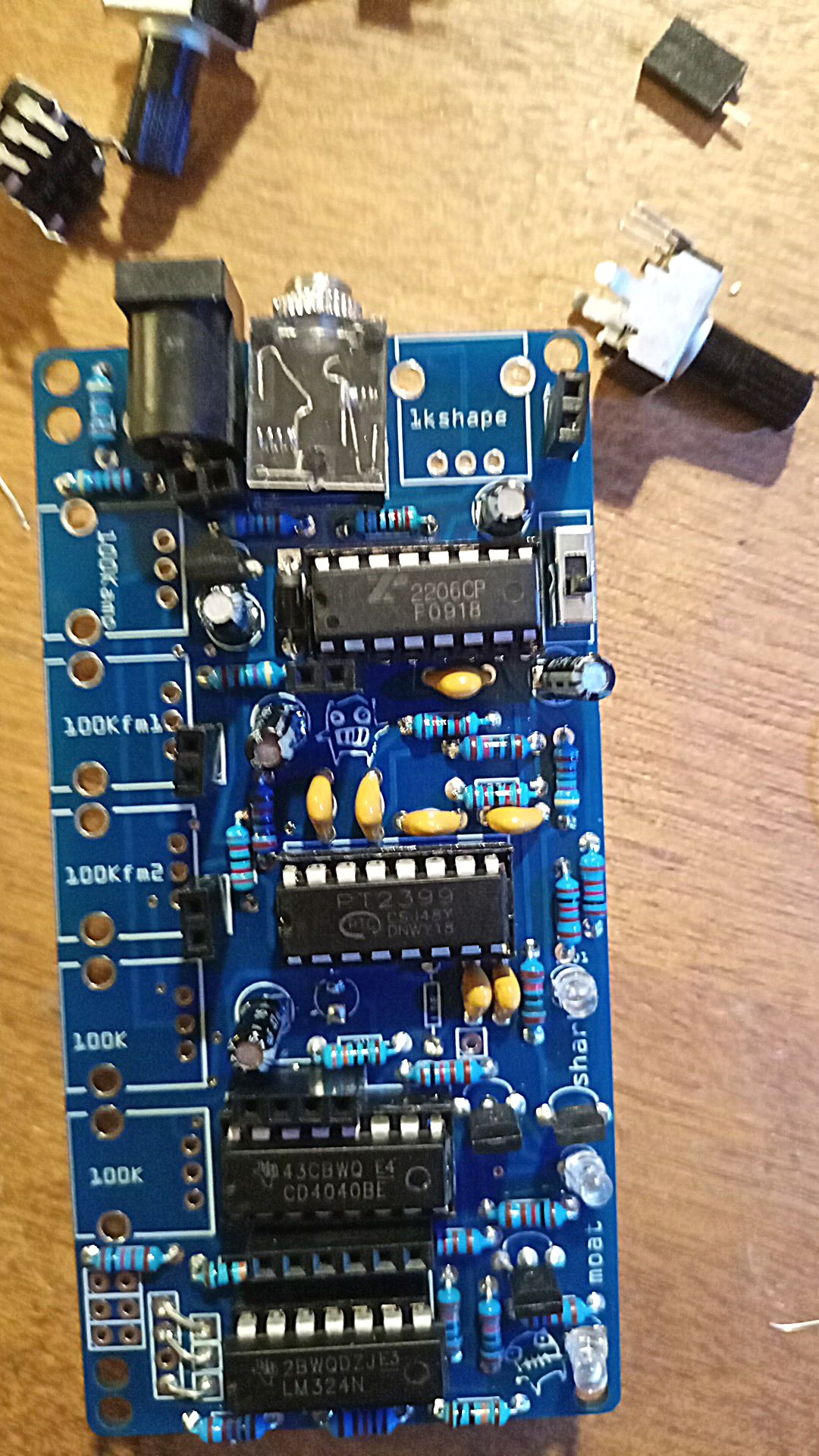

and then insert the ic chips into the sockets since it’s difficult to insert the chips if all the sockets are in place. then complete soldering the sockets.

inserted ICs

solder the power socket. ooh, getting closer ….

power socket

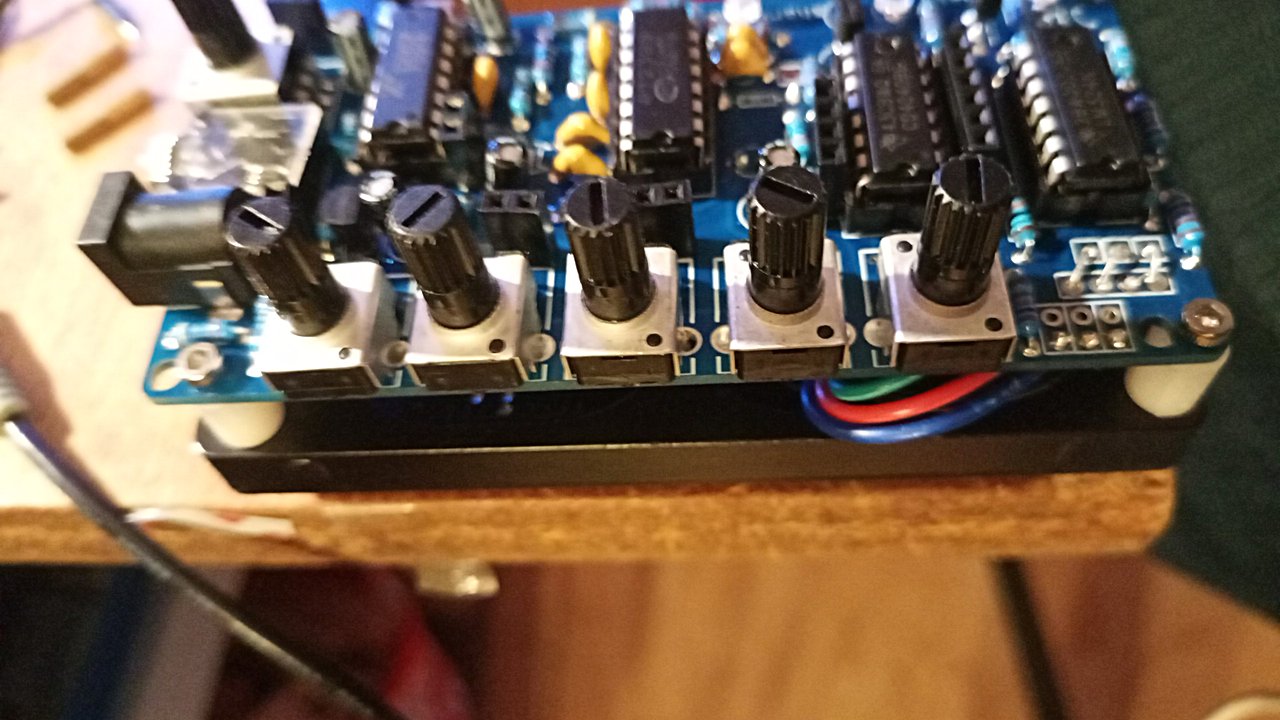

and now the pots. to keep them straight, always hold the pot flush, solder one of the 3 pins, turn over and check that it’s sitting flush, then complete the rest of the pins.

pots

back to the disk, we slide the wire assembly through the gap where the interface for the disk driver was and…

wires through gap

solder the black wire into the gap in the four pin assembly with the jumpers.

solder black wire to common row

now we complete the rest of the three remaining wires. Take your time. I tin these first after stripping to be able to push them through, but it can be fiddly.

motor wires solderd to outer row

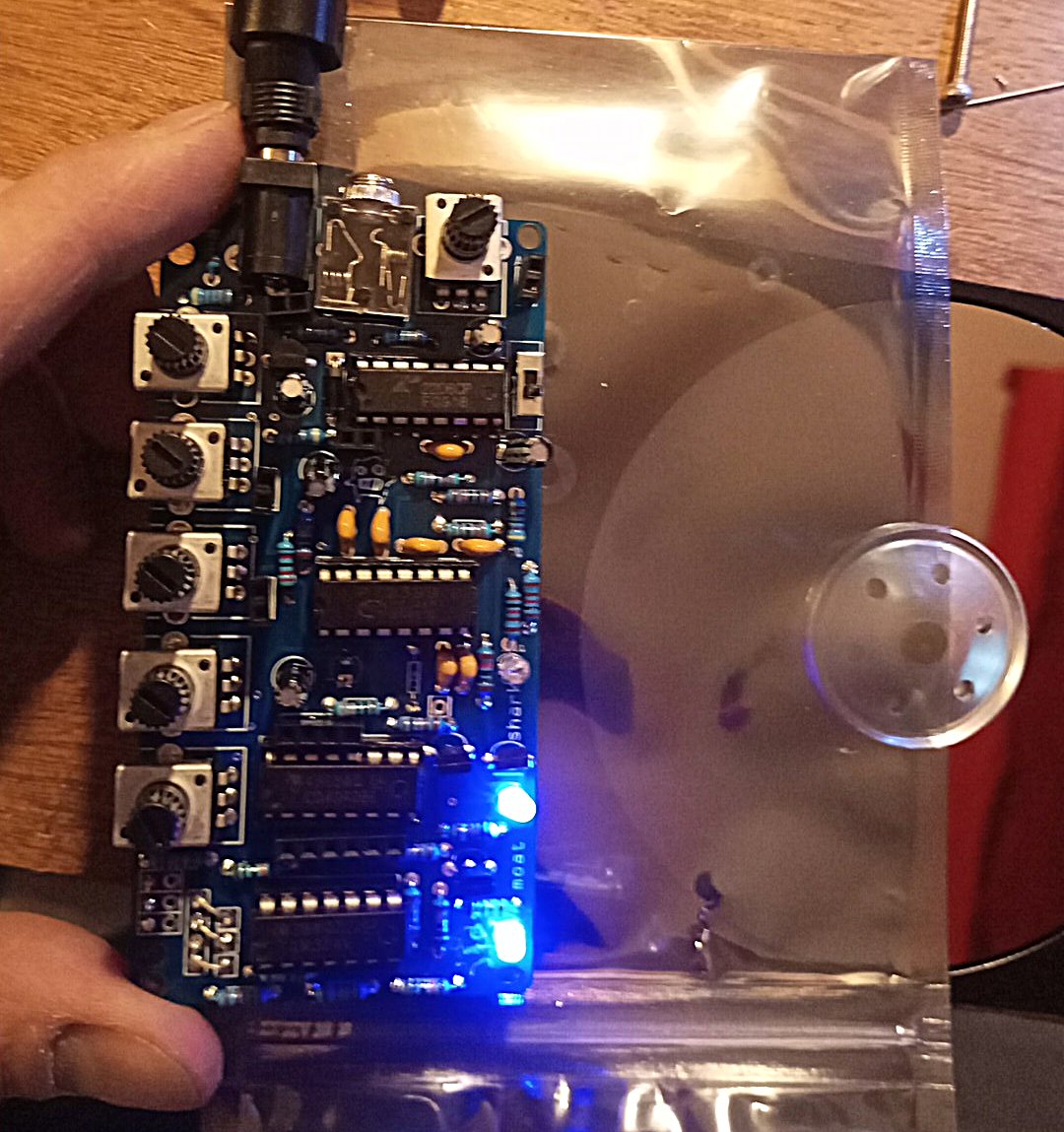

Oh, boy. Moment of truth! Now, I usually place something between the finished assembly and the disk (paper, antistatic bag as here) and do a first test. Important! make sure the bottom most pot is not turned all the way left. the 2399 might not boot it it’s hard left. It’s a design flaw :) Plug in sound and then power. Turn the DISK! do all the lights blink?!Does an apocalyptic sound emenate from the sound system?!

TEST!

Ok, on this build, it did not. I had to scrutinize my soldering. The lights DID blink, but no sound. So, I used a magnifying glass to identify where my soldering had been a bit sloppy. Test again, YE?AH!!!!! It’s all fine.

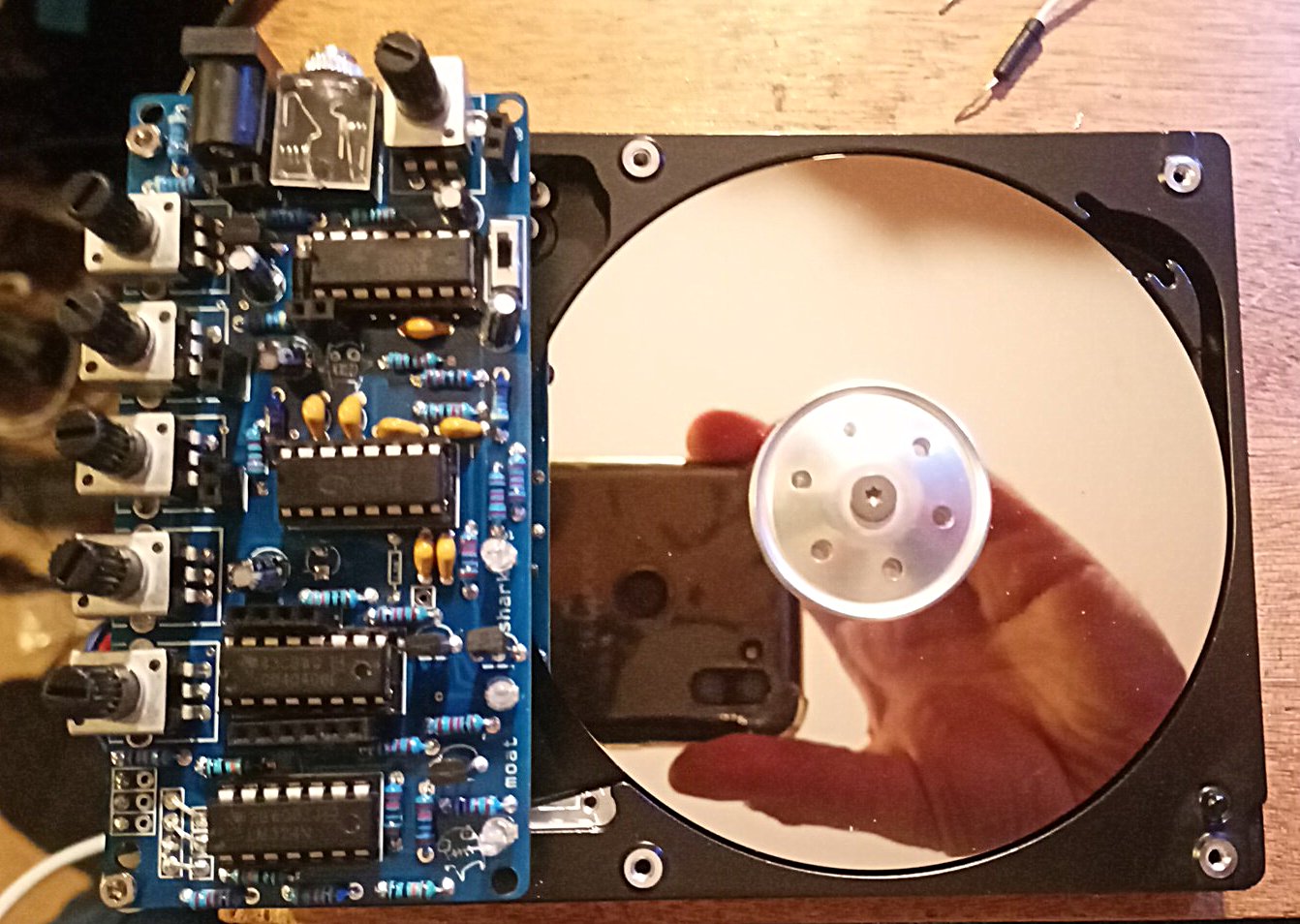

let’s move on to assembly. Take the two 8mm spacers and using the long 2.5 mm hex head screws (you’ll need a hex wrench!) affix the board as is seen here. There are multiple holes to permit using the board with different disk. But what you see here will work with disks I provide.

attach board to disk

Oh, this is looking pretty good!

hey, good lookin!

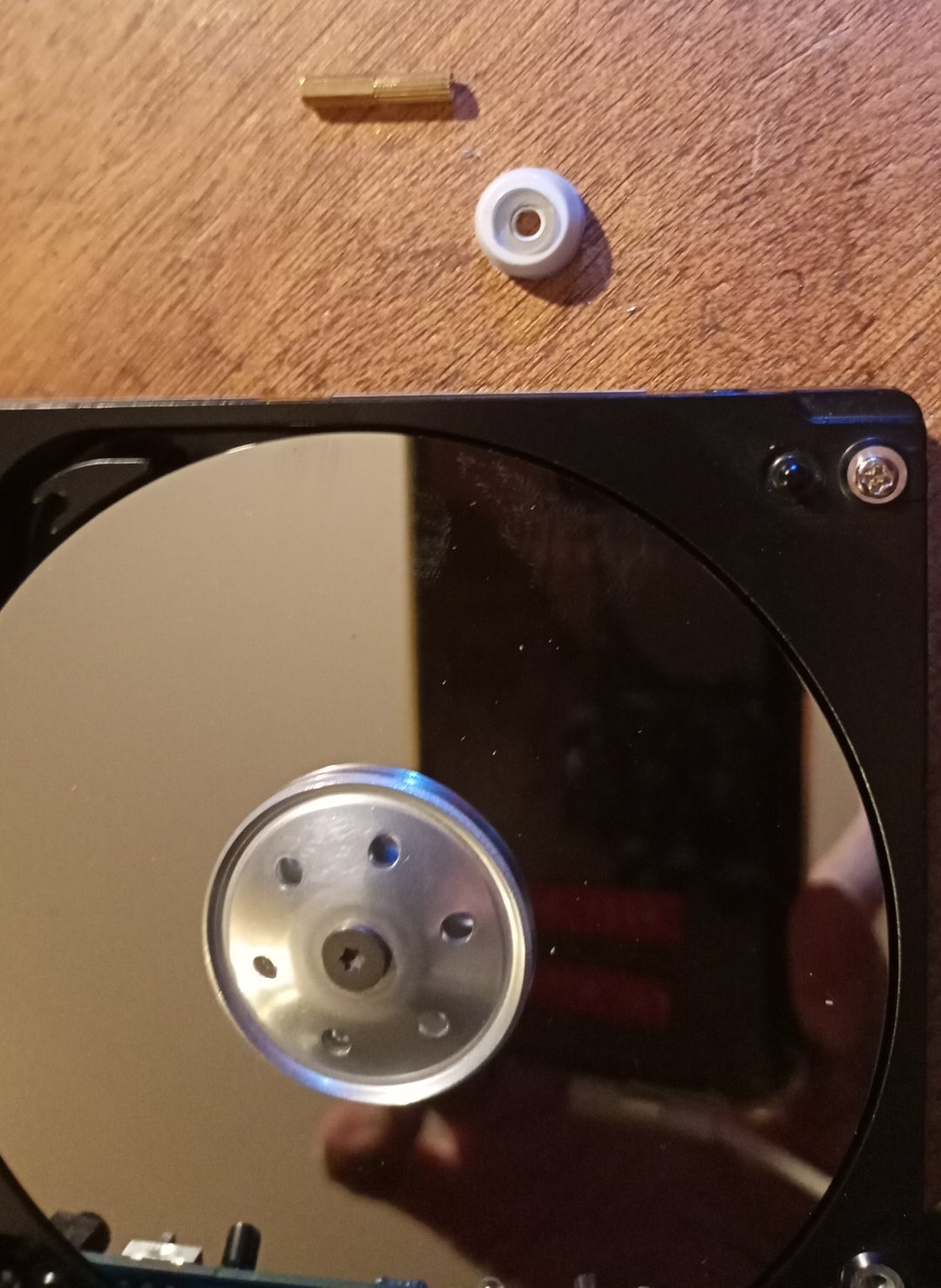

Now, on to the legs. I supply some slim 8x2 mm offsets that are affixed through the corner holes at the ‘front’. I supply short and long screws. The short one in the top …

leg spacers...

and affix the double offset as seen here using the longer screw through the white rubber foot.

leg spacers...

repeat for the right if you started on the left :)

leg spacers...

The remaing two feet are affixed with 3mm screws to the holes farthest to the ‘back’, nearest the board. Don’t overtighten these.

leg NO spacers...

And now, we add a bit of tape (or hot glue, bit I prefer to be able to easily remove it) to protect the motor contacts.

And we’re basically DONE!

Use nicer tape than this!

Ok. Go make some noise. Thank you for your attention :)